Loom

A loom is a device used to manufacture cloth. This machine produces fabric by interlacing a series of Warp yarn that is lengthwise parallel yarns with a series of weft yarn that is widthwise parallel yarns. The development of this machine made cloth much more affordable and available to a greater number of people. It is only used for weaving. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same.

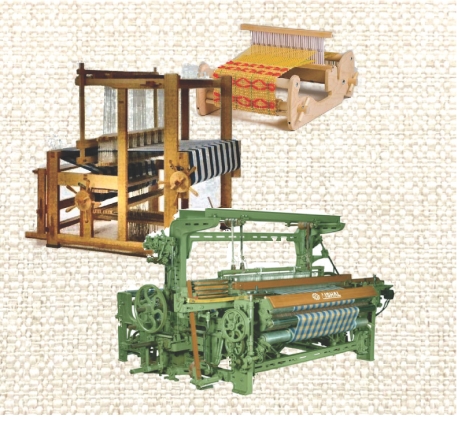

Different type of looms.

Hand loom

The handloom is a manually operated loom used to weave cloth without the aid of electric power. This is a woven fabric that uses mechanical energy of the weaver and the motion of the handloom is purely manually operated instead of use of electric energy.

Power loom

A power loom is a type of loom that is powered mechanically instead of using human power to weave patterns or thread into cloth. The power loom is an invention that combined threads to make cloth. Power looms were assembled in the weaving shed of a mill and driven by a steam engine by belts from overhead shafting. Power looms were a major advance over the hand looms used before.

Shuttle Loom

The shuttle loom is the oldest type of weaving loom which uses a shuttle that contains a pirn of filling weft yarn that appears through a hole situated in the side. The shuttle is batted across the loom. Although very effective and versatile, the shuttle looms are slow and noisy. Also, the shuttle sometimes leads to abrasion on the warp yarns and at other times causes thread breaks. As a result, the machine has to be stopped for tying the broken yarns.

Shuttle-less Loom

Weft is carried through projectiles, rapiers or fluids in case of shuttle-less looms. The rate of production is much higher for these looms. Besides, the quality of the products is also better and the product range much broader compared to that of Power looms. Most of the modern mills are equipped with different types of shuttle-less looms based on the product range.